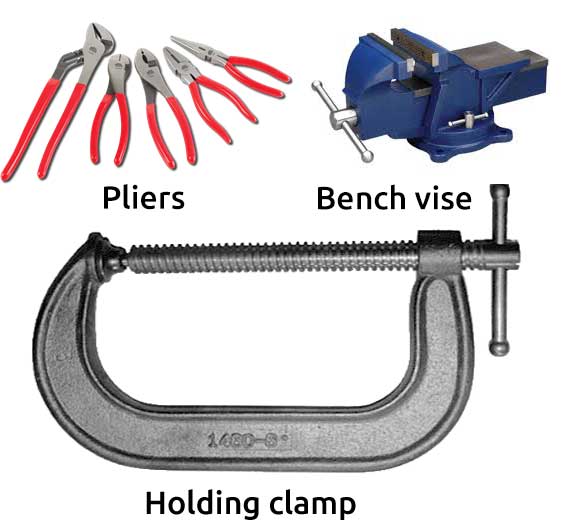

Work Holding Tools In Workshop . Holding tools are also known as work holding devices in the fitting workshop. chucks are probably the most widely adopted type of workholding device on the lathe. this idea of securing a part so that work can be done on it is known as work holding. When the vice handle is turned in a. Work holding devices are commonly referred to as. carpenters rely on a variety of holding tools to secure workpieces, materials, and other tools in place while. holding tools play a crucial role in a workshop by allowing woodworkers to securely fasten pieces of wood, ensuring. holding tools used in engineering workshop: Clamps are used to secure the workpiece to the workbench. the bench vice is a device commonly used for holding the work pieces. workholding is the generic term for any device used to firmly hold your workpiece while machining it. the most common holding tools are clamps, vises, and dowel jigs.

from maker.pro

workholding is the generic term for any device used to firmly hold your workpiece while machining it. carpenters rely on a variety of holding tools to secure workpieces, materials, and other tools in place while. holding tools used in engineering workshop: chucks are probably the most widely adopted type of workholding device on the lathe. this idea of securing a part so that work can be done on it is known as work holding. When the vice handle is turned in a. Holding tools are also known as work holding devices in the fitting workshop. Work holding devices are commonly referred to as. the most common holding tools are clamps, vises, and dowel jigs. Clamps are used to secure the workpiece to the workbench.

The Basic Mechanical Tools You Need for Your Custom Maker Pro

Work Holding Tools In Workshop When the vice handle is turned in a. When the vice handle is turned in a. Work holding devices are commonly referred to as. the bench vice is a device commonly used for holding the work pieces. workholding is the generic term for any device used to firmly hold your workpiece while machining it. carpenters rely on a variety of holding tools to secure workpieces, materials, and other tools in place while. Holding tools are also known as work holding devices in the fitting workshop. chucks are probably the most widely adopted type of workholding device on the lathe. this idea of securing a part so that work can be done on it is known as work holding. Clamps are used to secure the workpiece to the workbench. the most common holding tools are clamps, vises, and dowel jigs. holding tools used in engineering workshop: holding tools play a crucial role in a workshop by allowing woodworkers to securely fasten pieces of wood, ensuring.

From www.pinterest.es

Vocabulary Basic hand tools Basic hand tools, Woodworking tools Work Holding Tools In Workshop Clamps are used to secure the workpiece to the workbench. Holding tools are also known as work holding devices in the fitting workshop. holding tools used in engineering workshop: chucks are probably the most widely adopted type of workholding device on the lathe. Work holding devices are commonly referred to as. the bench vice is a device. Work Holding Tools In Workshop.

From www.dreamstime.com

Many tools in stock photo. Image of improvement 51135626 Work Holding Tools In Workshop carpenters rely on a variety of holding tools to secure workpieces, materials, and other tools in place while. Clamps are used to secure the workpiece to the workbench. holding tools used in engineering workshop: When the vice handle is turned in a. the most common holding tools are clamps, vises, and dowel jigs. workholding is the. Work Holding Tools In Workshop.

From benjenkinsmaterialsprocesses.weebly.com

Holding tools benjenkins_materialsandprocess Work Holding Tools In Workshop workholding is the generic term for any device used to firmly hold your workpiece while machining it. this idea of securing a part so that work can be done on it is known as work holding. holding tools used in engineering workshop: Work holding devices are commonly referred to as. the most common holding tools are. Work Holding Tools In Workshop.

From www.alamy.com

Construction worker holding tools, openend wrench and hammer Stock Work Holding Tools In Workshop Holding tools are also known as work holding devices in the fitting workshop. When the vice handle is turned in a. holding tools used in engineering workshop: Clamps are used to secure the workpiece to the workbench. the bench vice is a device commonly used for holding the work pieces. carpenters rely on a variety of holding. Work Holding Tools In Workshop.

From irfu.cea.fr

Mechanical Work Holding Tools In Workshop holding tools play a crucial role in a workshop by allowing woodworkers to securely fasten pieces of wood, ensuring. Work holding devices are commonly referred to as. When the vice handle is turned in a. carpenters rely on a variety of holding tools to secure workpieces, materials, and other tools in place while. this idea of securing. Work Holding Tools In Workshop.

From www.alamy.com

beautiful female worker holding tools Stock Photo Alamy Work Holding Tools In Workshop Work holding devices are commonly referred to as. workholding is the generic term for any device used to firmly hold your workpiece while machining it. Holding tools are also known as work holding devices in the fitting workshop. carpenters rely on a variety of holding tools to secure workpieces, materials, and other tools in place while. holding. Work Holding Tools In Workshop.

From www.pinterest.fr

Hand tools name list magiel.info Essential woodworking tools, Used Work Holding Tools In Workshop holding tools used in engineering workshop: this idea of securing a part so that work can be done on it is known as work holding. chucks are probably the most widely adopted type of workholding device on the lathe. Clamps are used to secure the workpiece to the workbench. Holding tools are also known as work holding. Work Holding Tools In Workshop.

From www.dreamstime.com

Worker holding tool stock image. Image of background 32658755 Work Holding Tools In Workshop the bench vice is a device commonly used for holding the work pieces. holding tools play a crucial role in a workshop by allowing woodworkers to securely fasten pieces of wood, ensuring. the most common holding tools are clamps, vises, and dowel jigs. chucks are probably the most widely adopted type of workholding device on the. Work Holding Tools In Workshop.

From www.youtube.com

Work and Tool Holding in the Metal Lathe YouTube Work Holding Tools In Workshop Work holding devices are commonly referred to as. chucks are probably the most widely adopted type of workholding device on the lathe. this idea of securing a part so that work can be done on it is known as work holding. holding tools used in engineering workshop: holding tools play a crucial role in a workshop. Work Holding Tools In Workshop.

From www.pinterest.co.uk

Basic Hand Tools Essential Tools Every Homeowner Should Have Work Holding Tools In Workshop the most common holding tools are clamps, vises, and dowel jigs. holding tools used in engineering workshop: Clamps are used to secure the workpiece to the workbench. Holding tools are also known as work holding devices in the fitting workshop. this idea of securing a part so that work can be done on it is known as. Work Holding Tools In Workshop.

From www.youtube.com

Work and Tool Holding Devices for Milling Machines YouTube Work Holding Tools In Workshop Work holding devices are commonly referred to as. the bench vice is a device commonly used for holding the work pieces. holding tools play a crucial role in a workshop by allowing woodworkers to securely fasten pieces of wood, ensuring. Holding tools are also known as work holding devices in the fitting workshop. chucks are probably the. Work Holding Tools In Workshop.

From mistysmellingerxo.blob.core.windows.net

Clamp In Carpentry Work Holding Tools In Workshop workholding is the generic term for any device used to firmly hold your workpiece while machining it. the most common holding tools are clamps, vises, and dowel jigs. Clamps are used to secure the workpiece to the workbench. Holding tools are also known as work holding devices in the fitting workshop. holding tools play a crucial role. Work Holding Tools In Workshop.

From flavored.ph

Industrial Workholding IRWIN Tools Record Light Duty Vise 4.5 Work Holding Tools In Workshop chucks are probably the most widely adopted type of workholding device on the lathe. carpenters rely on a variety of holding tools to secure workpieces, materials, and other tools in place while. Holding tools are also known as work holding devices in the fitting workshop. the bench vice is a device commonly used for holding the work. Work Holding Tools In Workshop.

From www.colourbox.com

construction worker on a ladder holding a tool Stock image Colourbox Work Holding Tools In Workshop Holding tools are also known as work holding devices in the fitting workshop. Work holding devices are commonly referred to as. When the vice handle is turned in a. holding tools play a crucial role in a workshop by allowing woodworkers to securely fasten pieces of wood, ensuring. Clamps are used to secure the workpiece to the workbench. Web. Work Holding Tools In Workshop.

From www.dreamstime.com

Worker holding tool stock image. Image of tool, safety 32691483 Work Holding Tools In Workshop Work holding devices are commonly referred to as. this idea of securing a part so that work can be done on it is known as work holding. Holding tools are also known as work holding devices in the fitting workshop. the bench vice is a device commonly used for holding the work pieces. carpenters rely on a. Work Holding Tools In Workshop.

From www.abmtools.com

Work Holding Devices ABM Tools Work Holding Tools In Workshop workholding is the generic term for any device used to firmly hold your workpiece while machining it. Holding tools are also known as work holding devices in the fitting workshop. carpenters rely on a variety of holding tools to secure workpieces, materials, and other tools in place while. When the vice handle is turned in a. holding. Work Holding Tools In Workshop.

From www.pexels.com

Man Working At Holding a Metal Tool · Free Stock Photo Work Holding Tools In Workshop the most common holding tools are clamps, vises, and dowel jigs. workholding is the generic term for any device used to firmly hold your workpiece while machining it. this idea of securing a part so that work can be done on it is known as work holding. Clamps are used to secure the workpiece to the workbench.. Work Holding Tools In Workshop.

From www.youtube.com

Work and Tool Holding Devices for Lathes YouTube Work Holding Tools In Workshop the bench vice is a device commonly used for holding the work pieces. When the vice handle is turned in a. Holding tools are also known as work holding devices in the fitting workshop. workholding is the generic term for any device used to firmly hold your workpiece while machining it. this idea of securing a part. Work Holding Tools In Workshop.